What is Industrial Oil : Guide to Their Types and Applications

Introduction: What Is Industrial Oil?

Industrial oils are a cornerstone of modern industries, ensuring that machinery and equipment function reliably under demanding conditions. These specialized oils are designed to meet the unique challenges posed by industrial environments, such as high pressures, extreme temperatures, and the need for precision. This guide explores industrial oils in depth, providing a detailed overview of their types and applications.

Industrial oils are much more than just lubricants; they are critical in enhancing machine efficiency, reducing wear and tear, and lowering energy consumption. In doing so, they contribute to overall operational sustainability, making them indispensable in sectors ranging from manufacturing to energy production.

Why Is Industrial Oil Important?

Reduces Friction: Enhances the smooth operation of moving parts.

Prevents Wear and Tear: Protects machinery from premature degradation.

Heat Dissipation: Regulates temperature by dissipating heat generated during operations.

Corrosion Resistance: Guards against rust and chemical damage.

Extended Equipment Life: Promotes longevity and cost-effectiveness.

The Vital Role of Industrial Oils

The primary role of industrial oil uses is to act as lubricants, reducing friction between moving parts and preventing wear. However, their importance goes far beyond lubrication. Industrial oils also:

Act as coolants by dissipating heat generated during operations.

Protect machinery from corrosion and rust.

Enhance the precision and efficiency of industrial processes.

Provide a barrier against contaminants, such as dust and water.

Their multifaceted roles ensure the smooth functioning of complex machinery, enabling industries to operate at optimal levels without frequent interruptions or costly maintenance.

Industrial Oil Types

Compressor Oils: Ensuring Compressed Air Systems Run Smoothly

Overview: Compressor oils are designed to lubricate and cool air compressors, reducing wear and preventing the build-up of deposits. These oils ensure efficient operation and extend the life of compressors.

Applications:

Used in rotary, reciprocating, and centrifugal compressors.

Ideal for industries such as manufacturing, construction, and automotive.

Benefits:

Minimizes friction and wear.

Enhances compressor efficiency.

Provides thermal stability.

Heat Transfer Fluids: The Unsung Heroes of Temperature Control

Overview: Heat transfer fluids are specialized oils used to transfer heat in systems like boilers and heat exchangers. They can withstand high temperatures while maintaining their thermal conductivity.

Applications:

Utilized in chemical plants, oil refineries, and food processing industries.

Suitable for heating and cooling systems.

Benefits:

Excellent thermal stability.

Reduces energy consumption.

Ensures consistent heat transfer.

Mould Release Oil: Facilitating Precision Manufacturing

Overview: Mould release oils are designed to prevent materials from sticking to mould surfaces. They are widely used in industries where casting and moulding are prevalent.

Applications:

Common in plastic, rubber, and concrete industries.

Ensures smooth demoulding processes.

Benefits:

Improves surface finish of moulded products.

Reduces production downtime.

Prolongs mould life.

Neat Cutting Oils: Elevating Metalworking Standards

Overview: Neat cutting oils are non-water-miscible oils used in machining processes. They provide lubrication and cooling to cutting tools.

Applications:

Suitable for turning, drilling, and milling operations.

Widely used in metalworking industries.

Benefits:

Enhances tool life.

Improves surface finish.

Reduces heat generation during machining.

Refrigeration Oils: Vital for Efficient Cooling Systems

Overview: Refrigeration oils are specially formulated to work in refrigeration and air conditioning systems. These oils are compatible with refrigerants and operate under extreme temperatures.

Applications:

Used in refrigerators, freezers, and HVAC systems.

Ideal for both commercial and residential setups.

Benefits:

Ensures efficient heat exchange.

Prevents wear and tear of components.

Offers excellent low-temperature fluidity.

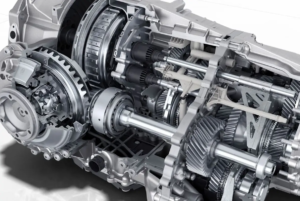

Gear Oils: Supporting Heavy-Duty Operations

Overview: Gear oils are designed to lubricate and protect gears, ensuring smooth transmission and reducing wear.

Applications:

Used in gearboxes of industrial machinery, vehicles, and wind turbines.

Suitable for both manual and automatic systems.

Benefits:

Protects against corrosion and wear.

Enhances load-carrying capacity.

Reduces operating noise.

Generator Oil: Powering Reliable Energy Solutions

Overview: Generator oils are essential for maintaining the performance of generators. They provide lubrication and ensure the engine runs smoothly.

Applications:

Used in power generation units, both portable and industrial.

Suitable for diesel and gas generators.

Benefits:

Prolongs engine life.

Reduces maintenance costs.

Improves fuel efficiency.

Hydraulic Oils: Enabling Precise Motion Control

Overview: Hydraulic oils are used in hydraulic systems to transmit power. They ensure smooth operation and protect components from wear.

Applications:

Common in construction equipment, manufacturing machinery, and automotive systems.

Used in forklifts, excavators, and cranes.

Benefits:

Provides excellent oxidation stability.

Reduces system downtime.

Enhances efficiency of hydraulic systems.

Transformer Oils: Ensuring Electrical Safety

Overview: Transformer oils are used as insulating and cooling mediums in transformers and electrical equipment.

Applications:

Ideal for power transformers, circuit breakers, and capacitors.

Used in both industrial and utility sectors.

Benefits:

Ensures efficient heat dissipation.

Prevents electrical discharge.

Offers long service life.

Turbine Oils: Meeting the Demands of Power Generation

Overview: Turbine oils are high-performance lubricants designed for steam, gas, and hydro turbines. They ensure reliable operation under extreme conditions.

Applications:

Used in power plants, aviation, and marine industries.

Suitable for steam and gas turbines.

Benefits:

Provides excellent oxidation stability.

Reduces sludge formation.

Enhances turbine efficiency.

Water Soluble Cutting Oils: Combining Cooling and Lubrication

Overview: Water soluble cutting oils are emulsifiable oils used in machining processes. They provide cooling and lubrication while being environmentally friendly.

Applications:

Common in industries like automotive, aerospace, and metal fabrication.

Used in grinding, drilling, and milling operations.

Benefits:

Reduces friction and heat.

Improves machining precision.

Eco-friendly and easy to clean.

Final Thoughts

Industrial oils are indispensable in ensuring the smooth functioning of machinery and systems across various industries. Each types of industrial oil serves a unique purpose, catering to specific operational requirements. By choosing the right industrial oil, businesses can enhance productivity, reduce maintenance costs, and extend the lifespan of their equipment.

For premium-quality industrial oils tailored to meet diverse industrial needs, trust Rumanza Industrial Oil. Our products are designed to deliver unmatched performance and reliability, ensuring your operations run seamlessly.

FAQs

Choosing the right industrial oil depends on several factors, including the type of machinery, operating temperature, pressure, and the oil’s intended purpose. For example, compressor oils are ideal for compressors, while gear oils are best suited for mechanical gear systems. Consult with manufacturers’ specifications or a lubrication expert to ensure you select the correct oil for your needs.

Gear oils are designed to lubricate gears and other mechanical parts in industrial machinery. They reduce friction, prevent wear, and dissipate heat generated from the movement of gears. Gear oils help increase the lifespan of machinery and improve its efficiency.

Hydraulic oil is specifically used in hydraulic systems to transfer energy within machinery, while engine oil is used for internal combustion engines to lubricate moving parts and prevent overheating. Hydraulic oils are often designed for higher pressures, while engine oils are formulated to handle heat and combustion-related stresses.

While some industrial oils, like multi-purpose oils, can be used across different machinery, it is important to choose the right oil for each application. Using the wrong type of oil can lead to equipment failure, reduced efficiency, and damage over time. Always consult the machinery manual or an expert for guidance.

The frequency of oil changes depends on the type of oil, machinery, and operating conditions. For instance, oils used in high-temperature environments may degrade faster and require more frequent changes. Always follow the manufacturer’s recommendations and monitor the oil’s performance to determine the right maintenance schedule.

Extend Your Tractor’s Lifespan with Rumanza UTTO Oil – A Comprehensive Guide

Extend Your Tractor’s Lifespan with Rumanza UTTO Oil – A Comprehensive Guide Discover More Tractors are the backbone of modern agriculture, performing demanding tasks such as plowing, tilling, hauling, and powering attachments. Given their heavy workload, ensuring optimal performance and longevity is crucial. One of the most effective ways to protect your tractor’s critical systems is by using Rumanza UTTO (Universal Tractor Transmission Oil), a high-performance lubricant engineered to enhance durability, efficiency, and reliability. The Science Behind UTTO Oil: Why It

Best Agriculture Tractor Oil: RUMANZA Trac-92 T Explained in Depth

Best Agriculture Tractor Oil: RUMANZA Trac-92 T Explained in Depth Discover More Agriculture tractors are indispensable in modern farming, serving as the primary workhorses for plowing, tilling, planting, and harvesting. However, the efficiency, durability, and overall performance of these machines depend significantly on the quality of the tractor engine oil used. Selecting the right agriculture tractor oil is not just about lubrication; it directly impacts fuel efficiency, engine longevity, and operational costs. Among the various options available, RUMANZA Trac-92 T has emerged as a leading high-performance tractor

Upgrade Your Drive with Rumanza CVT NSIII – Benefits & Features

Upgrade Your Drive with Rumanza CVT NSIII Benefits & Features Discover More The automotive industry is undergoing rapid advancements, with manufacturers continuously innovating to improve fuel efficiency, driving comfort, and engine performance. One of the most critical yet often overlooked components in modern vehicles is the transmission system, specifically the Continuously Variable Transmission (CVT). Unlike traditional automatic transmissions, CVTs provide seamless gear transitions, leading to smoother acceleration, better fuel economy, and reduced engine strain. Understanding CVT Technology and the Need

Rumanza Dual Clutch Transmission: Analysis of Advantages, Limitations, and Industry Impact

Rumanza Dual Clutch Transmission: Analysis of Its Advantages, Limitations, and Industry Impact Discover More The automotive industry is undergoing a transformative phase, with manufacturers relentlessly pushing the boundaries of performance, efficiency, and driving engagement. Among the most groundbreaking innovations in recent years is the Dual Clutch Transmission (DCT), a sophisticated gearbox technology that bridges the gap between manual and automatic transmissions. Rumanza, a pioneering name in transmission systems, has introduced an advanced DCT that is redefining expectations in terms of

Rumanza Gasoline Petrochemicals: A Strategic Force in the Global Energy Sector

Rumanza Gasoline Petrochemicals: A Strategic Force in the Global Energy Sector Discover More Rumanza Gasoline Petrochemicals: Corporate Overview & Market Dominance 1.1 Historical Evolution & Industry Positioning Founded in the late 20th century, Rumanza Gasoline Petrochemicals began as a regional fuel supplier before rapidly expanding into a vertically integrated energy conglomerate. Today, it operates: 12+ high-capacity refineries (crude processing capacity: 2.5 million barrels per day) 40+ petrochemical plants producing ethylene, propylene, benzene, and specialty chemicals Global supply chain networks across Asia, Africa, Europe, and the Americas Market Share & Financial

What Is Diesel Fuel Oil: Benefits & Types of Diesel Fuel

What Is Diesel Fuel Oil: Benefits & Types of Diesel Fuel Discover More Diesel fuel oil is one of the most crucial energy sources powering global industries, from transportation and agriculture to construction, power generation, and shipping. Its efficiency, reliability, and ability to produce high torque and power make it the preferred fuel for heavy-duty machinery, trucks, buses, and generators. But what exactly is diesel fuel oil? What are its benefits, types, and environmental impact? And how is the diesel

What Are the Benefits of Using Rumanza Trac-92 T Over Conventional Oils?

What Are the Benefits of Using Rumanza Trac-92 T Over Conventional Oils? Discover More Lubrication is essential for the efficient operation of machinery, engines, and industrial equipment. Choosing the right lubricant can significantly impact performance, durability, and operational costs. Rumanza Trac-92 T is an advanced lubricant that outperforms conventional oils in various aspects. This article explores the key benefits of using Rumanza Trac-92 T and why it is a superior choice over traditional lubricants. Superior Thermal Stability One of the

Choosing the Right Rumanza 2 Stroke TC-W3 Oil for Your Needs

Choosing the Right Rumanza 2 Stroke TC-W3 Oil for Your Needs Discover More Selecting the right 2-stroke engine oil is not just about lubrication—it’s about maximizing performance, reducing wear, and ensuring engine longevity. Rumanza TC-W3 oil is a trusted choice among marine and small engine users, but with multiple formulations available, making the best selection requires a deeper understanding. Understanding TC-W3 Certification: Why It’s Crucial for Your Engine The TC-W3 standard, established by the National Marine Manufacturers Association (NMMA), is the highest performance rating for

Rumanza 2 Stroke TC Oil Review: Is It Worth the Hype?

Rumanza 2 Stroke TC Oil Review: Is It Worth the Hype? Discover More When it comes to maintaining the performance and longevity of your 2-stroke engine, the choice of oil plays a pivotal role. Among the myriad of options available, Rumanza 2 Stroke TC Oil has emerged as a popular choice, garnering significant attention for its advanced formulation and performance claims. But does it truly live up to the hype? In this in-depth review, we’ll explore every facet of Rumanza

Discover Rumanza Water Soluble Cutting Oil Benefits | Expert Insights

Rumanza Water Soluble Cutting Oil Benefits | Expert Insights Discover More In the fast-paced world of metalworking and machining, the choice of cutting fluids is critical to achieving precision, efficiency, and cost-effectiveness. Among the myriad options available, Rumanza Water Soluble Cutting Oil has emerged as a leading solution, trusted by industries worldwide. This article provides an in-depth exploration of the benefits of Rumanza Water Soluble Cutting Oil, offering expert insights into its formulation, applications, and advantages. Whether you’re a machinist,