What is Group II Base Oils and Characteristics also Thermal and Oxidative Stability?

Preface

Production of Group II Base Oils

Group II base oils are manufactured through a process called hydrocracking, which is more complex and intensive than the solvent refining used for Group I oils. Hydrocracking not only removes more impurities but also saturates the oil with hydrogen, making the oil purer and more stable. This process involves high pressures and temperatures, and the presence of a catalyst, which breaks down larger molecules into more useful ones. This refining method distinguishes Group II base oils by providing them with lower sulfur content and a higher percentage of saturates compared to Group I oils.

Characteristics of Group II Base Oils

Group II base oils are characterized by their high level of saturation and low sulfur content. These oils typically have a viscosity index ranging from 80 to 120, making them versatile for various applications. They possess better antioxidative properties than Group I oils due to their purer hydrocarbon base, which includes fewer impurities. Additionally, their lower volatility reduces oil loss and enhances performance at high temperatures. The improved characteristics of Group II base oils make them suitable for a wider range of applications, offering a balance between performance and cost.

Thermal and Oxidative Stability

Applications of Group II Base Oils

Environmental and Regulatory Considerations

Primary refining techniques for Group II base oils

How does the viscosity index of Group II base oils affect their application?

Market Trends and Future Outlook

Final Thoughts

FAQs

Extend Your Tractor’s Lifespan with Rumanza UTTO Oil – A Comprehensive Guide

Extend Your Tractor’s Lifespan with Rumanza UTTO Oil – A Comprehensive Guide Discover More Tractors are the backbone of modern agriculture, performing demanding tasks such as plowing, tilling, hauling, and powering attachments. Given their heavy workload, ensuring optimal performance and longevity is crucial. One of the most effective ways to protect your tractor’s critical systems is by using Rumanza UTTO (Universal Tractor Transmission Oil), a high-performance lubricant engineered to enhance durability, efficiency, and reliability. The Science Behind UTTO Oil: Why It

Best Agriculture Tractor Oil: RUMANZA Trac-92 T Explained in Depth

Best Agriculture Tractor Oil: RUMANZA Trac-92 T Explained in Depth Discover More Agriculture tractors are indispensable in modern farming, serving as the primary workhorses for plowing, tilling, planting, and harvesting. However, the efficiency, durability, and overall performance of these machines depend significantly on the quality of the tractor engine oil used. Selecting the right agriculture tractor oil is not just about lubrication; it directly impacts fuel efficiency, engine longevity, and operational costs. Among the various options available, RUMANZA Trac-92 T has emerged as a leading high-performance tractor

Upgrade Your Drive with Rumanza CVT NSIII – Benefits & Features

Upgrade Your Drive with Rumanza CVT NSIII Benefits & Features Discover More The automotive industry is undergoing rapid advancements, with manufacturers continuously innovating to improve fuel efficiency, driving comfort, and engine performance. One of the most critical yet often overlooked components in modern vehicles is the transmission system, specifically the Continuously Variable Transmission (CVT). Unlike traditional automatic transmissions, CVTs provide seamless gear transitions, leading to smoother acceleration, better fuel economy, and reduced engine strain. Understanding CVT Technology and the Need

Rumanza Dual Clutch Transmission: Analysis of Advantages, Limitations, and Industry Impact

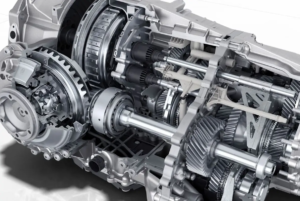

Rumanza Dual Clutch Transmission: Analysis of Its Advantages, Limitations, and Industry Impact Discover More The automotive industry is undergoing a transformative phase, with manufacturers relentlessly pushing the boundaries of performance, efficiency, and driving engagement. Among the most groundbreaking innovations in recent years is the Dual Clutch Transmission (DCT), a sophisticated gearbox technology that bridges the gap between manual and automatic transmissions. Rumanza, a pioneering name in transmission systems, has introduced an advanced DCT that is redefining expectations in terms of

Rumanza Gasoline Petrochemicals: A Strategic Force in the Global Energy Sector

Rumanza Gasoline Petrochemicals: A Strategic Force in the Global Energy Sector Discover More Rumanza Gasoline Petrochemicals: Corporate Overview & Market Dominance 1.1 Historical Evolution & Industry Positioning Founded in the late 20th century, Rumanza Gasoline Petrochemicals began as a regional fuel supplier before rapidly expanding into a vertically integrated energy conglomerate. Today, it operates: 12+ high-capacity refineries (crude processing capacity: 2.5 million barrels per day) 40+ petrochemical plants producing ethylene, propylene, benzene, and specialty chemicals Global supply chain networks across Asia, Africa, Europe, and the Americas Market Share & Financial