Lithium Grease Explained: Uses, Benefits, and Applications

What is Lithium Grease?

As formulated, lithium grease is a multi-purpose grease with a thickening agent derived from lithium hydroxide. Its color is usually white or light, while it has a smooth and buttery texture that makes it easy to apply. It diminishes friction well, aids in the prevention of rust and corrosion, and tolerates extreme temperatures; hence it is suitable for various applications.

Lithium Grease Properties

High Melting Point: Lithium grease has a high dropping point (the temperature at which it starts to melt), typically around 190-220°C (374-428°F), allowing it to perform well in high-temperature environments.

Water Resistance: It offers excellent resistance to water washout, making it ideal for applications exposed to moisture, rain, or humidity.

Oxidation Stability: Lithium grease maintains its lubricating properties over time, even in harsh conditions, which helps extend the life of the machinery or components.

Adhesive Properties: It sticks well to metal surfaces, ensuring long-lasting lubrication and reducing the need for frequent reapplication.

Versatility: Lithium grease can be used in a wide range of applications, from automotive and industrial machinery to household appliances.

Types of Lithium Grease

There are several types of lithium grease available, each designed for specific applications:

Lithium Complex Grease: This grease contains complexing agents that enhance its properties, such as higher temperature resistance, improved water resistance, and increased load-carrying capacity. It is commonly used in heavy-duty industrial applications.

White Lithium Grease: This type is the most common and versatile form of lithium grease. It is suitable for general-purpose lubrication tasks, including automotive, marine, and household applications. Its white color makes it easy to identify and monitor the application.

Moly Lithium Grease: This grease contains molybdenum disulfide (moly), which provides additional protection against extreme pressure and heavy loads. It is ideal for applications involving high stress, such as automotive chassis, bearings, and construction equipment.

What is Lithium Grease Used For

Lithium grease uses in a wide variety of lithium grease applications across different industries due to its versatility and excellent lubrication properties. Here are some of the most common uses:

1. Automotive Applications

- Chassis Lubrication: Lithium grease is often used for lubricating chassis components, such as ball joints, tie rod ends, and suspension parts. Its ability to withstand high temperatures and resist water makes it ideal for these applications.

- Wheel Bearings: Many automotive enthusiasts and mechanics use lithium grease for wheel bearings, especially in trailers and light trucks. It provides long-lasting lubrication and protects against corrosion.

- Door Hinges and Locks: White lithium grease is perfect for lubricating door hinges, locks, and latches, ensuring smooth operation and reducing squeaks.

2. Industrial Applications

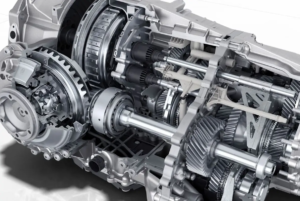

- Machinery Lubrication: In industrial settings, lithium grease is widely used for lubricating bearings, gears, and other moving parts of machinery. It helps reduce friction, wear, and tear, thereby extending the life of the equipment.

- Electric Motors: Due to its excellent water resistance and high-temperature stability, lithium grease is suitable for lubricating electric motor bearings, ensuring smooth operation and reducing the risk of overheating.

3. Household Applications

- Appliance Maintenance: Lithium grease is ideal for maintaining household appliances, such as garage door tracks, hinges, and sliding doors. It ensures smooth movement and prevents rust and corrosion.

- Bicycle Maintenance: Cyclists often use white lithium grease to lubricate bike chains, gears, and other moving parts, ensuring optimal performance and reducing wear and tear.

4. Marine Applications

- Boat Trailers: Lithium grease’s water resistance makes it perfect for lubricating boat trailer wheel bearings and other components exposed to water.

- Marine Engines: It provides effective lubrication for marine engines, protecting against rust and corrosion in a water-rich environment.

Benefits of Using Lithium Grease

Lithium grease is pretty versatile and advantageous in a great number of lubrication applications. Some key benefits of lithium grease are as follows:

- Long-lasting lubrication: It adheres pretty well to surfaces, thus providing excellent long-lasting lubrication properties and minimizes the necessity of reapplying it frequently.

- Water Resistance: This is a great characteristic that makes it very appropriate for applications exposed to moisture, like marine and outdoor equipment.

- High temperature resistance: Lithium greases can tolerate heavy temperatures-they are used for automotive and industrial applications whereby there is a possibility of temperatures affecting the application.

- Corrosion Protection: It creates a protective barrier on metal surfaces that helps to check the corrosion and rust.

- Versatility: It can range from automotive to a house due to the fact that it can accommodate a wide application scope.

How to Apply Lithium Grease

Proper application of lithium grease ensures optimal performance and extends the life of your equipment. Here’s a step-by-step guide on how to apply it:

- Clean the Surface: Before applying lithium grease, clean the surface thoroughly to remove dirt, dust, and old grease. This ensures proper adhesion and effective lubrication.

- Apply the Grease: Use a grease gun, brush, or your fingers to apply a thin, even layer of lithium grease to the surface. Avoid over-applying, as excess grease can attract dirt and debris.

- Reapply as Needed: Monitor the lubrication periodically and reapply as needed, especially in high-use or high-stress applications.

Choosing the Right Lithium Grease for Your Needs

Selecting the right type of lithium grease depends on the specific application and operating conditions. Here are some factors to consider when choosing the right lithium grease:

- Temperature Range: Consider the temperature range of the application. For high-temperature environments, opt for lithium complex grease.

- Load-Carrying Capacity: If the application involves heavy loads or high pressure, choose moly lithium grease for added protection.

- Water Exposure: For applications exposed to water or moisture, select a grease with superior water resistance, such as white lithium grease.

Final Thoughts

It is considered one of those extremely versatile greases which encompasses a wide range of uses from the application in automotive and industrial use to household and marine tasks. Owing to its high-temperature stability, water resistance, and long-lasting lubrication, lithium grease has emerged as one of the most widely used greases for a number of lubrication requirements. It can be confidently decided which type of lithium grease to use for specific applications if different types of this grease are understood.

Whether you are maintaining a vehicle, lubricating industrial machinery, or making sure household appliances are running smoothly, lithium grease is the answer to quality lubrication and protection. Includes lithium grease in your regular maintenance schedule and assures that friction is reduced, corrosion is prevented and, thus, the lifespan of your costly equipment is extended.

FAQs

Calcium Grease: Great water resistance, low-temperature use.

Lithium Grease: Better for high temperatures and more versatile, suitable for various applications.

Lithium grease offers better high-temperature stability, water resistance, and versatility compared to regular greases made with different thickeners.

- Limited performance under extreme pressure

- Not ideal for high-speed bearings

- Environmental concerns

- Limited chemical resistance

Alternatives include calcium sulfonate grease (water-resistant), polyurea grease (high temperature), silicone grease (for rubber/plastic), and PTFE grease (chemical resistance).

- Silicone Grease: Best for rubber, plastic, and electrical applications.

- Lithium Grease: Ideal for metal-to-metal lubrication in automotive and industrial uses.

Best Agriculture Tractor Oil: RUMANZA Trac-92 T Explained in Depth

Best Agriculture Tractor Oil: RUMANZA Trac-92 T Explained in Depth Discover More Agriculture tractors are indispensable in modern farming, serving as the primary workhorses for plowing, tilling, planting, and harvesting. However, the efficiency, durability, and overall performance of these machines depend significantly on the quality of the tractor engine oil used. Selecting the right agriculture tractor oil is not just about lubrication; it directly impacts fuel efficiency, engine longevity, and operational costs. Among the various options available, RUMANZA Trac-92 T has emerged as a leading high-performance tractor

Upgrade Your Drive with Rumanza CVT NSIII – Benefits & Features

Upgrade Your Drive with Rumanza CVT NSIII Benefits & Features Discover More The automotive industry is undergoing rapid advancements, with manufacturers continuously innovating to improve fuel efficiency, driving comfort, and engine performance. One of the most critical yet often overlooked components in modern vehicles is the transmission system, specifically the Continuously Variable Transmission (CVT). Unlike traditional automatic transmissions, CVTs provide seamless gear transitions, leading to smoother acceleration, better fuel economy, and reduced engine strain. Understanding CVT Technology and the Need

Rumanza Dual Clutch Transmission: Analysis of Advantages, Limitations, and Industry Impact

Rumanza Dual Clutch Transmission: Analysis of Its Advantages, Limitations, and Industry Impact Discover More The automotive industry is undergoing a transformative phase, with manufacturers relentlessly pushing the boundaries of performance, efficiency, and driving engagement. Among the most groundbreaking innovations in recent years is the Dual Clutch Transmission (DCT), a sophisticated gearbox technology that bridges the gap between manual and automatic transmissions. Rumanza, a pioneering name in transmission systems, has introduced an advanced DCT that is redefining expectations in terms of

Rumanza Gasoline Petrochemicals: A Strategic Force in the Global Energy Sector

Rumanza Gasoline Petrochemicals: A Strategic Force in the Global Energy Sector Discover More Rumanza Gasoline Petrochemicals: Corporate Overview & Market Dominance 1.1 Historical Evolution & Industry Positioning Founded in the late 20th century, Rumanza Gasoline Petrochemicals began as a regional fuel supplier before rapidly expanding into a vertically integrated energy conglomerate. Today, it operates: 12+ high-capacity refineries (crude processing capacity: 2.5 million barrels per day) 40+ petrochemical plants producing ethylene, propylene, benzene, and specialty chemicals Global supply chain networks across Asia, Africa, Europe, and the Americas Market Share & Financial

What Is Diesel Fuel Oil: Benefits & Types of Diesel Fuel

What Is Diesel Fuel Oil: Benefits & Types of Diesel Fuel Discover More Diesel fuel oil is one of the most crucial energy sources powering global industries, from transportation and agriculture to construction, power generation, and shipping. Its efficiency, reliability, and ability to produce high torque and power make it the preferred fuel for heavy-duty machinery, trucks, buses, and generators. But what exactly is diesel fuel oil? What are its benefits, types, and environmental impact? And how is the diesel

What Are the Benefits of Using Rumanza Trac-92 T Over Conventional Oils?

What Are the Benefits of Using Rumanza Trac-92 T Over Conventional Oils? Discover More Lubrication is essential for the efficient operation of machinery, engines, and industrial equipment. Choosing the right lubricant can significantly impact performance, durability, and operational costs. Rumanza Trac-92 T is an advanced lubricant that outperforms conventional oils in various aspects. This article explores the key benefits of using Rumanza Trac-92 T and why it is a superior choice over traditional lubricants. Superior Thermal Stability One of the

Choosing the Right Rumanza 2 Stroke TC-W3 Oil for Your Needs

Choosing the Right Rumanza 2 Stroke TC-W3 Oil for Your Needs Discover More Selecting the right 2-stroke engine oil is not just about lubrication—it’s about maximizing performance, reducing wear, and ensuring engine longevity. Rumanza TC-W3 oil is a trusted choice among marine and small engine users, but with multiple formulations available, making the best selection requires a deeper understanding. Understanding TC-W3 Certification: Why It’s Crucial for Your Engine The TC-W3 standard, established by the National Marine Manufacturers Association (NMMA), is the highest performance rating for