Grease Oil Guide: Types, Applications, Uses, and Benefits

What is Grease Oil?

Types of Grease Oil

Understanding the different types of grease oil is crucial for selecting the right product for your specific needs. Here’s an in-depth look at the most common types:

1. Lithium-Based Grease

Properties: Lithium-based grease is known for its excellent water resistance, good thermal stability, and versatility. It can withstand moderate to high temperatures and is suitable for a wide range of applications.

Applications: Widely used in automotive chassis, industrial machinery, and household appliances. Lithium complex greases are particularly popular for their enhanced performance in high-temperature and high-load conditions.

2. Calcium-Based Grease

- Properties: Calcium-based grease offers superior water resistance and adhesion, making it ideal for wet or humid environments. It also has good mechanical stability and anti-corrosion properties.

Applications: Commonly used in marine equipment, agricultural machinery, and food processing plants. Calcium sulfonate grease, a subtype, is highly valued for its extreme pressure (EP) and anti-rust capabilities.

3. Polyurea Grease

Properties: Polyurea grease is known for its high thermal stability, oxidation resistance, and long service life. It is also non-conductive, making it suitable for electric motor bearings.

Applications: Ideal for sealed-for-life applications, high-speed machinery, and electric motor bearings. Its ability to resist oxidation and maintain performance over time makes it a cost-effective choice for many industries.

4. Silicone Grease

Properties: Silicone grease has a wide temperature range, chemical inertness, and compatibility with plastics and rubber. It is also water-resistant and non-conductive.

Applications: Used in O-rings, gaskets, rubber components, and electrical connectors. It is also popular in applications requiring non-reactive lubricants, such as medical devices and laboratory equipment.

5. Aluminum Complex Grease

Properties: Aluminum complex grease offers excellent extreme pressure (EP) properties, corrosion resistance, and thermal stability. It is also highly adhesive, making it suitable for heavy-duty applications.

Applications: Commonly used in steel mills, mining equipment, and heavy-duty industrial machinery. Its ability to withstand high loads and harsh environments makes it a preferred choice for demanding applications.

6. Bentonite Grease

Properties: Bentonite grease, made from clay thickeners, has a high dropping point and excellent thermal stability. It does not melt at high temperatures, making it ideal for extreme heat conditions.

Applications: Used in ovens, kilns, and high-temperature industrial processes. It is also suitable for applications where traditional grease would break down due to heat.

Applications of Grease Oil

Grease oil is used in a wide range of industries due to its versatility and effectiveness. Here’s a detailed look at its applications:

1. Automotive Industry

Uses: Lubricating wheel bearings, chassis components, universal joints, and suspension systems.

Benefits: Reduces friction, prevents corrosion, and extends the lifespan of vehicle components. High-performance greases also improve fuel efficiency by reducing energy loss due to friction.

2. Industrial Machinery

Uses: Lubricating gears, bearings, chains, and other moving parts in manufacturing plants and factories.

Benefits: Enhances operational efficiency, reduces downtime, and minimizes wear and tear on equipment.

3. Marine Industry

Uses: Protecting equipment from saltwater corrosion, lubricating winches, cables, and deck machinery.

Benefits: Ensures reliable performance in harsh marine environments and extends the life of marine equipment.

4. Aerospace Industry

Uses: Lubricating aircraft landing gear, actuators, control systems, and other critical components.

Benefits: Withstands extreme temperatures and pressures, ensuring the safety and reliability of aircraft systems.

5. Food Processing Industry

Uses: Lubricating equipment in food production lines, such as mixers, conveyors, and packaging machines.

Benefits: Safe for incidental food contact and compliant with health regulations, ensuring the safety and quality of food products.

Uses of Grease Oil

Grease oil serves multiple purposes across various sectors. Here are some common uses:

Reducing Friction: Minimizes wear and tear between moving parts, improving efficiency and longevity.

Preventing Corrosion: Forms a protective barrier against moisture and contaminants, reducing the risk of rust and corrosion.

Sealing Out Contaminants: Keeps dirt, dust, and debris away from critical components, maintaining cleanliness and performance.

Dampening Noise: Reduces operational noise in machinery, creating a quieter working environment.

Extending Equipment Life: Enhances the durability and performance of mechanical systems, reducing maintenance costs.

Benefits of Grease Oil

The benefits of grease oil make it a preferred choice for lubrication in many industries. Here are the key advantages:

Long-Lasting Lubrication: Grease oil adheres to surfaces, providing continuous lubrication over extended periods.

Versatility: Suitable for a wide range of temperatures, pressures, and environments.

Cost-Effectiveness: Reduces maintenance costs by minimizing equipment wear and downtime.

Environmental Resistance: Performs well in wet, dusty, or corrosive conditions.

Enhanced Safety: Reduces the risk of mechanical failures and accidents, ensuring safe and reliable operations.

Latest Trends in Grease Oil Technology

The grease oil industry is constantly evolving to meet the demands of modern machinery and environmental regulations. Here are some latest trends:

Bio-Based Greases: Made from renewable resources, these greases are eco-friendly and biodegradable, reducing environmental impact.

High-Performance Synthetic Greases: Designed for extreme conditions, such as high temperatures and heavy loads, offering superior performance and longevity.

Smart Greases: Embedded with sensors to monitor lubrication levels and equipment health in real-time, enabling predictive maintenance.

Nanotechnology: Incorporates nanoparticles to enhance lubrication properties and reduce friction at the molecular level, improving efficiency and performance.

How to Choose the Right Grease Oil

Selecting the appropriate grease oil depends on several factors:

Operating Conditions: Consider temperature, pressure, and environmental factors.

Equipment Requirements: Check the manufacturer’s recommendations for compatibility and performance.

Compatibility: Ensure the grease is compatible with other lubricants and materials used in your equipment.

Performance Additives: Look for additives that address specific challenges, such as extreme pressure or corrosion resistance.

Maintenance Tips for Grease Oil

Proper maintenance is essential to maximize the benefits of grease oil. Here are some tips:

Regular Reapplication: Follow the manufacturer’s guidelines for reapplication intervals.

Clean Equipment: Remove old grease and contaminants before applying new grease.

Monitor Performance: Check for signs of wear, noise, or overheating, which may indicate inadequate lubrication.

Store Properly: Keep grease in a cool, dry place to prevent degradation.

Final Thoughts

FAQs

Mixing greases with different thickeners or base oils can reduce performance and cause compatibility issues. Always consult the manufacturer’s guidelines before mixing.

Extend Your Tractor’s Lifespan with Rumanza UTTO Oil – A Comprehensive Guide

Extend Your Tractor’s Lifespan with Rumanza UTTO Oil – A Comprehensive Guide Discover More Tractors are the backbone of modern agriculture, performing demanding tasks such as plowing, tilling, hauling, and powering attachments. Given their heavy workload, ensuring optimal performance and longevity is crucial. One of the most effective ways to protect your tractor’s critical systems is by using Rumanza UTTO (Universal Tractor Transmission Oil), a high-performance lubricant engineered to enhance durability, efficiency, and reliability. The Science Behind UTTO Oil: Why It

Best Agriculture Tractor Oil: RUMANZA Trac-92 T Explained in Depth

Best Agriculture Tractor Oil: RUMANZA Trac-92 T Explained in Depth Discover More Agriculture tractors are indispensable in modern farming, serving as the primary workhorses for plowing, tilling, planting, and harvesting. However, the efficiency, durability, and overall performance of these machines depend significantly on the quality of the tractor engine oil used. Selecting the right agriculture tractor oil is not just about lubrication; it directly impacts fuel efficiency, engine longevity, and operational costs. Among the various options available, RUMANZA Trac-92 T has emerged as a leading high-performance tractor

Upgrade Your Drive with Rumanza CVT NSIII – Benefits & Features

Upgrade Your Drive with Rumanza CVT NSIII Benefits & Features Discover More The automotive industry is undergoing rapid advancements, with manufacturers continuously innovating to improve fuel efficiency, driving comfort, and engine performance. One of the most critical yet often overlooked components in modern vehicles is the transmission system, specifically the Continuously Variable Transmission (CVT). Unlike traditional automatic transmissions, CVTs provide seamless gear transitions, leading to smoother acceleration, better fuel economy, and reduced engine strain. Understanding CVT Technology and the Need

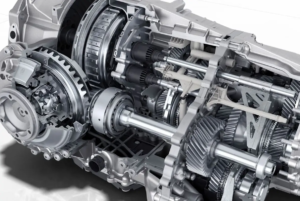

Rumanza Dual Clutch Transmission: Analysis of Advantages, Limitations, and Industry Impact

Rumanza Dual Clutch Transmission: Analysis of Its Advantages, Limitations, and Industry Impact Discover More The automotive industry is undergoing a transformative phase, with manufacturers relentlessly pushing the boundaries of performance, efficiency, and driving engagement. Among the most groundbreaking innovations in recent years is the Dual Clutch Transmission (DCT), a sophisticated gearbox technology that bridges the gap between manual and automatic transmissions. Rumanza, a pioneering name in transmission systems, has introduced an advanced DCT that is redefining expectations in terms of

Rumanza Gasoline Petrochemicals: A Strategic Force in the Global Energy Sector

Rumanza Gasoline Petrochemicals: A Strategic Force in the Global Energy Sector Discover More Rumanza Gasoline Petrochemicals: Corporate Overview & Market Dominance 1.1 Historical Evolution & Industry Positioning Founded in the late 20th century, Rumanza Gasoline Petrochemicals began as a regional fuel supplier before rapidly expanding into a vertically integrated energy conglomerate. Today, it operates: 12+ high-capacity refineries (crude processing capacity: 2.5 million barrels per day) 40+ petrochemical plants producing ethylene, propylene, benzene, and specialty chemicals Global supply chain networks across Asia, Africa, Europe, and the Americas Market Share & Financial

What Is Diesel Fuel Oil: Benefits & Types of Diesel Fuel

What Is Diesel Fuel Oil: Benefits & Types of Diesel Fuel Discover More Diesel fuel oil is one of the most crucial energy sources powering global industries, from transportation and agriculture to construction, power generation, and shipping. Its efficiency, reliability, and ability to produce high torque and power make it the preferred fuel for heavy-duty machinery, trucks, buses, and generators. But what exactly is diesel fuel oil? What are its benefits, types, and environmental impact? And how is the diesel

What Are the Benefits of Using Rumanza Trac-92 T Over Conventional Oils?

What Are the Benefits of Using Rumanza Trac-92 T Over Conventional Oils? Discover More Lubrication is essential for the efficient operation of machinery, engines, and industrial equipment. Choosing the right lubricant can significantly impact performance, durability, and operational costs. Rumanza Trac-92 T is an advanced lubricant that outperforms conventional oils in various aspects. This article explores the key benefits of using Rumanza Trac-92 T and why it is a superior choice over traditional lubricants. Superior Thermal Stability One of the

Choosing the Right Rumanza 2 Stroke TC-W3 Oil for Your Needs

Choosing the Right Rumanza 2 Stroke TC-W3 Oil for Your Needs Discover More Selecting the right 2-stroke engine oil is not just about lubrication—it’s about maximizing performance, reducing wear, and ensuring engine longevity. Rumanza TC-W3 oil is a trusted choice among marine and small engine users, but with multiple formulations available, making the best selection requires a deeper understanding. Understanding TC-W3 Certification: Why It’s Crucial for Your Engine The TC-W3 standard, established by the National Marine Manufacturers Association (NMMA), is the highest performance rating for