Furnace Oil and Lubricants: A Guide to Maximizing Equipment Life

In industries where heavy machinery is the backbone of production, ensuring the longevity and efficiency of equipment is vital. One of the most critical factors in maintaining and extending the life of industrial machinery is proper lubrication and the use of high-quality furnace oil. This guide will provide you with a comprehensive overview of furnace oil and lubricants, highlighting their roles in maximizing equipment life. We’ll also explore how the right choices in fuel oil furnaces, alongside regular maintenance and lubrication, can result in cost savings and enhanced operational efficiency.

What is Furnace Oil?

Furnace oil or furnace fuel oil is a type of fuel oil used predominantly in industrial boilers and furnaces for generating heat. It is a byproduct of crude oil and is highly viscous, requiring preheating before use in equipment. Best oil furnaces has a high calorific value, making it a preferred choice in industries that demand continuous, high-heat operations.

It refers to a unit of the furnace in which fuel fossil is consumed while heat is being transferred. Oil furnaces as well as the natural gas-fueled one are available types. An oil furnace is any heating system used to burn the fuel oil as a means to warm your house. Oil furnaces are, in fact common in colder-weather climates across the northeastern parts of the United States.

Furnace oil is mainly used in industries like power generation, steel, textiles, and chemical processing. Its cost-effectiveness and high efficiency in generating heat make it a popular option in industrial settings.

Key Properties of Furnace Oil:

High Calorific Value: Ensures efficient energy production.

Viscosity: Enables sustained combustion in industrial furnaces.

Stability: Prolongs shelf life and maintains consistent performance.

Typical Performance

How does an oil furnace work?

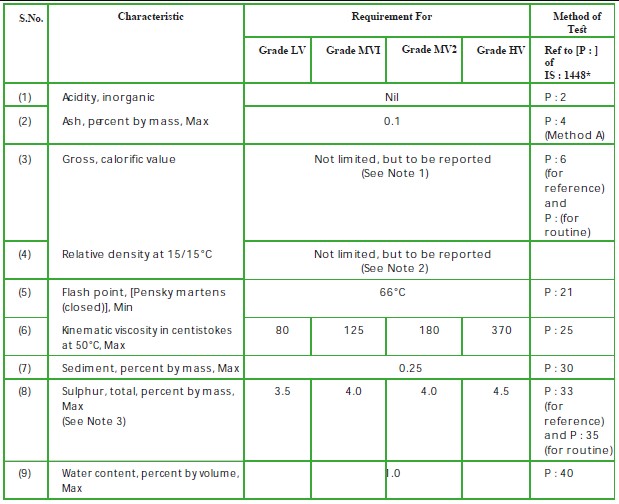

Types of Furnace Oils

Furnace oils come in different grades, ranging from lighter to heavier variants. The type of furnace oil you choose should depend on your equipment’s specific requirements and the operating conditions. Lighter oils tend to burn more efficiently, while heavier oils may provide a more sustained energy release.

When looking for the best oil furnaces, it’s essential to consider not only the type of oil used but also the furnace’s compatibility with that oil. Modern fuel oil furnace systems are often designed to handle a range of oil types, providing flexibility for industries that rely on varied fuel sources.

What’s the difference between an oil furnace and a gas furnace?

Pros and cons of oil furnaces

Pros:

- High Heat Output: Oil furnaces produce a high level of heat, making them ideal for colder climates where more heating power is needed.

- Independence from Gas Supply: Oil furnaces can operate in areas without access to natural gas lines, providing a reliable heating option.

- Affordable Equipment: The upfront cost of an oil furnace is often lower than other heating systems.

- Longevity: With proper maintenance, oil furnaces can last 15–25 years, offering long-term value.

- Energy Independence: Fuel oil can be stored on-site, giving homeowners control over their fuel supply.

Cons:

- Lower Efficiency: Oil furnaces tend to be less energy-efficient than gas furnaces, often resulting in higher fuel consumption.

- Maintenance Requirements: They require regular upkeep, including cleaning of burners and changing of filters, to prevent soot buildup and maintain efficiency.

- Cost of Fuel: Heating oil prices can fluctuate significantly, making annual heating expenses less predictable.

- Environmental Concerns: Burning oil emits more greenhouse gases compared to natural gas, contributing more to pollution.

- Storage Space: A storage tank for oil is necessary, which can take up significant space and may require periodic inspection and replacement.

Common Uses of Furnace Oil

Furnace oil finds application across various industries due to its reliability and cost-effectiveness:

Power Generation: A primary fuel for thermal power plants.

Industrial Heating: Used in kilns, boilers, and furnaces.

Marine Industry: Powers large engines in ships.

For those seeking reliable furnace oil suppliers in the UAE, the region boasts a robust market catering to industrial and commercial needs.

Fuel Oil Furnace: An Essential Tool for High-Efficiency Heating

A fuel oil furnace is specially designed to burn fuel oil like furnace oil, converting it into heat energy to power industrial operations. These furnaces are highly efficient, especially when the fuel oil is preheated for optimal combustion. Investing in a high-quality fuel oil furnace can help industries maximize energy efficiency while minimizing operational costs.

Role of Lubricants in Equipment Maintenance

While furnace oil is essential for heat generation, lubricants play a crucial role in reducing friction between the moving parts of machinery. Friction is one of the leading causes of equipment wear and tear. By minimizing friction, lubricants help extend the life of equipment, prevent breakdowns, and enhance overall efficiency.

Types of Lubricants Used in Industrial Equipment

- Mineral Oils: These are the most common lubricants derived from refining crude oil. They offer good stability and viscosity and are widely used in various industrial applications.

- Synthetic Oils: Offering better performance than mineral oils, synthetic oils provide improved resistance to oxidation and thermal breakdown, especially in high-temperature environments.

- Greases: These are semi-solid lubricants, often used in applications where liquid oils would leak away, such as in bearings or heavy-load machinery.

Regular use of lubricants prevents metal parts from grinding against each other, which in turn reduces the frequency of repairs and prolongs the life of the machinery.

Best Practices for Selecting the Best Oil Furnace

Choosing the best oil furnaces for your industrial operations involves several critical factors. Selecting the right furnace can have a profound impact on energy consumption, operational costs, and environmental sustainability.

Factors to Consider:

- Energy Efficiency: Opt for an oil furnace with a high Annual Fuel Utilization Efficiency (AFUE) rating. A higher AFUE means more energy is being converted into heat rather than wasted.

- Cost: The upfront cost of a furnace is important, but it’s also crucial to consider long-term operational costs. A cheaper oil furnace may result in higher energy bills and frequent maintenance.

- Size and Capacity: The oil furnace should be appropriately sized for the space it needs to heat. Oversized furnaces waste energy, while undersized ones may not meet operational demands.

- Environmental Impact: Look for oil furnaces that meet modern emissions standards to reduce your carbon footprint. Some modern oil furnaces now come with cleaner burning technology, making them more eco-friendly.

When selecting the best oil furnace, keep in mind your long-term goals in terms of efficiency and sustainability.

The Interplay Between Furnace Oil and Lubricants

Both furnace oil and lubricants play complementary roles in ensuring the longevity of industrial equipment. While furnace oil powers the heat generation process, lubricants ensure that the machinery runs smoothly without excessive wear and tear. The two work together to reduce operational costs and minimize downtime, ultimately enhancing overall productivity.

For example, in a steel plant, where heat generation is a constant necessity, using high-quality furnace oil ensures consistent heat output. At the same time, regular lubrication of the moving parts of the machinery prevents mechanical failures, ensuring that the production line continues without interruptions.

Maintaining Your Oil Furnace for Maximum Efficiency

Proper maintenance of your oil furnace is essential for maximizing its life and operational efficiency. Regular inspections and upkeep will not only extend the lifespan of the furnace but also prevent unexpected breakdowns that could disrupt industrial processes.

Used Oil Furnace Maintenance Tips:

- Regular Inspections: Schedule routine checks for any signs of wear, corrosion, or damage. Inspections will help identify potential issues before they become major problems.

- Clean Fuel Lines: Furnace oil can leave deposits in the fuel lines over time, reducing efficiency. Clean the fuel lines regularly to ensure smooth flow and optimal performance.

- Check for Fuel Leaks: Even small leaks can result in significant losses over time. Ensure that all fuel connections are tight and that no fuel is being wasted.

- Lubricate Moving Parts: Regularly lubricate the blower motor and other moving parts to prevent excessive friction and wear.

Following these best practices will ensure that your used oil furnace operates efficiently and effectively, minimizing downtime and maintenance costs.

Cost Considerations and Furnace Oil Prices

The cost of furnace oil can vary significantly based on factors such as location, crude oil prices, and demand. Monitoring furnace oil prices is critical for businesses relying on this fuel for their operations, as fluctuations in cost can directly impact their bottom line.

Strategies to Manage Furnace Oil Costs:

- Bulk Purchasing: Buying furnace oil in bulk can help lower the price per unit, especially when demand is low.

- Energy Audits: Conduct regular energy audits to identify areas where energy usage can be optimized. This can lead to more efficient use of furnace oil and reduce overall consumption.

- Regular Maintenance: Ensuring your furnace and machinery are in good working order can help prevent inefficiencies that lead to increased fuel consumption.

Investing in high-quality furnace oil and ensuring your equipment is properly maintained can help you avoid the pitfalls of fluctuating oil prices and unexpected equipment failures.

Waste Oil Furnace: A Sustainable Alternative

As industries prioritize sustainability, waste oil furnaces have gained traction. These systems recycle used oils, converting them into usable energy, reducing environmental impact, and lowering operational costs.

Benefits of Waste Oil Furnaces:

Environmental Conservation: Minimizes waste disposal issues.

Cost-Effectiveness: Reuses waste oils effectively.

Energy Efficiency: Provides consistent heating solutions.

Leading Suppliers in the UAE

If you are searching for reliable furnace oil suppliers in UAE the region offers unparalleled options, known for their commitment to quality and timely delivery. Whether it’s furnace oil suppliers in Dubai or other emirates, the UAE stands as a beacon for industrial excellence.

Final Thoughts

Choosing the right furnace oil and lubricants is crucial to maximizing the lifespan of your equipment. Whether you are running a fuel oil furnace or a used oil furnace, the quality of the oil and lubricants you use, combined with a proactive maintenance schedule, will have a significant impact on equipment performance. By staying informed about furnace oil prices and ensuring proper lubrication, businesses can reduce operational costs, prevent breakdowns, and extend the life of their valuable machinery.

FAQs

Radiator Stop Leak UAE: Quick Fix for Vehicle Cooling System Leaks

Radiator Stop Leak UAE: Quick Fix for Vehicle Cooling System Leaks Discover More Introduction: The Unforgiving UAE Climate and Your Vehicle’s Lifeline The United Arab Emirates’ automotive landscape is defined by extremes. Ambient temperatures that regularly surpass 45°C (113°F), coupled with intense urban congestion and long, high-speed desert drives, create a perfect storm of thermal stress for every vehicle. In this environment, your engine cooling system is not merely a subsystem; it is the single most critical component preventing catastrophic engine failure.

What Type of Transmission Oil in UAE Does My Car Need? Your Complete Guide

What Type of Transmission Oil in UAE Does My Car Need? Your Complete Guide Discover More Navigating the vast, sun-baked highways of the United Arab Emirates—from the dynamic urban sprawls of Dubai and Abu Dhabi to the majestic desert dunes and the tranquil mountain passes of the Hajar range—places extraordinary mechanical and thermal stress on every component of your vehicle. While conscientious drivers often prioritize engine oil changes, the vital lifeblood safeguarding the transmission, the complex heart of your car’s

Guide to UAE Turbine Oil Selection Application & Management for Industrial Facilities

Guide to UAE Turbine Oil Selection, Application, and Management for Industrial Facilities Discover More In the hyper-competitive industrial landscape of the United Arab Emirates, where operational excellence directly translates to economic advantage, turbine lubrication represents a critical nexus of reliability engineering and strategic asset management. This comprehensive guide, developed with technical insights from Rumanza Lubricants, provides an unprecedented deep dive into the science, selection criteria, and life-cycle management of turbine oils specifically engineered for the extreme operating conditions of the

Synthetic vs. Mineral Hydraulic Oil in UAE : Which is Best for Your Operation?

Synthetic vs. Mineral Hydraulic Oil in UAE : Which is Best for Your Operation? Discover More Across the dynamic landscape of the United Arab Emirates—from the megaprojects of Dubai Marina to the intricate conveyor systems of Jebel Ali Port, from the massive hydraulic shovels in Al Dhafra quarries to the precision automated lines in Abu Dhabi’s industrial cities—the silent, powerful force of hydraulics is indispensable. These systems convert fluid power into monumental force and precise motion. At the core of

What is a Pour Point Depressant? | Benefits, Uses & How It Works Mechanism

What is a Pour Point Depressant? | Benefits, Uses & How It Works Mechanism Discover More In the intricate world of lubricant formulation, few additives play as critical yet understated a role in cold-weather operability as Pour Point Depressants (PPDs). These specialized chemical compounds are the linchpin that prevents machinery from seizing up when temperatures plummet. This in-depth guide goes beyond the basics, exploring the sophisticated chemistry, detailed mechanism, nuanced benefits, and practical considerations of PPDs. We will also examine the

Guide to Gasoline Engine Oils for UAE’s Extreme Climate: Engineering Peak Performance

Gasoline Engine Oils for UAE’s Extreme Climate: Engineering Peak Performance Discover More In the heart of the Arabian Peninsula, the United Arab Emirates stands as a testament to human ambition, with its engineering marvels and endless highways. Yet, this environment of soaring achievement is also one of the most punishing on Earth for machinery. For your vehicle—whether a nimble city sedan, a powerful family SUV, or a high-performance sports car—the UAE’s climate is a relentless adversary. The choice of engine

What are Polyol Ester Oils & Lubricants – Properties & Applications

What are Polyol Ester Oils & Lubricants – Properties & Applications Discover More In the intricate world of industrial machinery, automotive engines, and advanced refrigeration systems, the choice of lubricant is not merely a maintenance task—it’s a critical engineering decision. While conventional mineral oils have served us for over a century, the demands of modern technology require fluids that can perform under extreme pressure, temperature, and environmental stress. This is where synthetic lubricants, specifically Polyol Ester oils, come to the forefront.

Guide to Choosing the Right Lithium Complex Grease in UAE

Guide to Choosing the Right Lithium Complex Grease in UAE for Unbeatable Performance Discover More In the heart of a region defined by its ambition and extreme climate, the machinery that builds and powers the UAE operates under immense pressure. From the towering cranes sculpting Dubai’s skyline to the massive haul trucks in Abu Dhabi’s industrial zones and the relentless conveyor systems in Jebel Ali Port, every moving part is a critical link in the chain of progress. Protecting these

Lithium Grease UAE – Buy Multi-Purpose Lubricant Grease

Lithium Grease UAE – Buy Multi-Purpose Lubricant Grease Discover More In the relentless engine of the United Arab Emirates’ economy—where monumental construction, non-stop logistics, and a climate of extreme heat and abrasive sand are the norm—the battle against friction and corrosion is perpetual. The integrity of a construction crane’s slewing ring, the smooth operation of a delivery fleet’s wheel bearings, and the silent efficiency of a hotel’s HVAC system all hinge on a single, critical decision: the choice of lubricant.

Best CNG Engine Oil in UAE for Cars – Protect Your CNG Engine

Best CNG Engine Oil in UAE for Cars – Protect Your CNG Engine Discover More The automotive landscape in the UAE is undergoing a quiet revolution. As fuel prices fluctuate and environmental consciousness grows, more and more drivers are making the intelligent switch to Compressed Natural Gas (CNG). CNG-powered cars offer significant cost savings on fuel and produce fewer emissions, making them an economically and ecologically sound choice. However, this transition comes with a critical responsibility: understanding that a CNG