Agricultural Engine Oil: Types, Uses & Choosing the Right Oil for Your Farm

What is Agricultural Engine Oil?

Agricultural engine oil is a specialized lubricant designed for engines used in farming equipment or agriculture vehicle oil for strong engines for agriculture. It is formulated to handle the unique demands of agricultural machinery, including tractors, combines, and harvesters. These oils must provide robust protection against wear, resist oxidation and thermal breakdown, and maintain viscosity under severe operating conditions. By ensuring smooth engine performance, agricultural engine oil helps reduce downtime and extend the lifespan of farm equipment, ultimately supporting the productivity and efficiency of farming operations.

Process and Manufacturing of Agricultural Engine Oil

The manufacturing process of agricultural engine oil involves several key steps to ensure high quality and performance. First, base oils are selected, typically derived from refined crude oil or synthetic sources. These base oils provide the fundamental lubrication properties. Next, various additives are blended into the base oils. These additives may include detergents, dispersants, anti-wear agents, antioxidants, and viscosity improvers, each contributing to the oil’s overall effectiveness. The blending process is carefully controlled to achieve the desired balance of properties. Finally, the oil undergoes rigorous testing to ensure it meets industry standards and specifications, ensuring it can withstand the demanding conditions of agricultural use.

Different Types of Agricultural Engine Oil

There are several types of agricultural engine oils, each designed to meet specific needs and operating conditions. The most common types include mineral oils, synthetic oils, and semi-synthetic oils. Mineral oils are derived from crude oil and offer basic lubrication properties. Synthetic oils are chemically engineered to provide superior performance, especially in extreme temperatures and heavy-duty applications. Semi-synthetic oils combine the benefits of both mineral and synthetic oils, offering a balance of cost and performance. Additionally, agricultural engine oils may vary by viscosity grade, such as SAE 30, SAE 15W-40, or SAE 10W-30, to accommodate different engine designs and operating environments.

There are several types for farm lubricants available, each with its own unique characteristics and applications. Some common types include:

- General-purpose oils for general use

- High-temperature oils for extreme heat conditions

- Low-temperature oils for cold weather operation

- Synthetic oils for extreme pressure and temperature conditions

- Bio-based oils for environmentally friendly options

Properties of Agricultural Engine Oil

Agricultural engine oils possess several critical properties that ensure optimal performance and protection for farm machinery. Key properties include high thermal stability, which prevents breakdown at elevated temperatures, and excellent viscosity control, which ensures consistent lubrication under varying temperatures and loads. These oils also offer strong anti-wear protection, minimizing engine component wear and extending equipment life. Additionally, they contain detergents and dispersants to keep engines clean by preventing the formation of sludge and deposits. Good oxidation resistance prevents the oil from degrading over time, and corrosion inhibitors protect engine parts from rust and corrosion.

Agricultural engine oils have several key properties that make them effective for use in farm equipment. These include:

- Viscosity: The ability to flow easily at various temperatures

- Lubricity: The ability to reduce friction and wear on moving parts

- Rust prevention: The ability to protect metal components from corrosion

- Wear protection: The ability to prevent wear on moving parts

Advantages of Agricultural Engine Oil

Using the right agricultural engine oil offers numerous advantages for farm machinery. Firstly, it ensures efficient engine operation, reducing wear and tear and prolonging the life of the equipment. The high-quality lubrication provided by these oils minimizes friction, enhancing fuel efficiency and reducing energy consumption. The superior thermal stability and oxidation resistance of agricultural engine oils help maintain performance under demanding conditions, such as extreme temperatures and heavy loads. Additionally, the detergent and dispersant additives keep engines clean, preventing sludge buildup and ensuring smooth operation. Overall, using the appropriate agricultural engine oil contributes to lower maintenance costs, fewer breakdowns, and increased productivity on the farm.

Using agricultural engine oil offers several advantages, including:

- Improved engine performance and efficiency

- Extended engine life and reduced maintenance costs

- Protection against corrosion and wear

- Compatibility with various materials and components

How to Choose the Right Agricultural Engine Oil

Choosing the right agricultural engine oil involves considering several factors to ensure optimal performance and protection for your machinery. Start by consulting the equipment manufacturer’s recommendations, which provide specific requirements for oil type and viscosity. Consider the operating conditions, such as temperature ranges and workload, to select an oil that can withstand these demands. Synthetic oils may be preferable for extreme conditions, while mineral oils can suffice for standard operations. Additionally, look for oils that meet or exceed industry standards and certifications, ensuring high quality and reliability. Regularly reviewing and adhering to these guidelines will help maintain your equipment’s efficiency and longevity.

Choosing the right agricultural engine oil requires considering several factors, including:

- Climate and operating conditions

- Type of equipment and manufacturer recommendations

- Oil viscosity and performance requirements

- Budget and cost considerations

Premium Agricultural Oils and Engine Maintenance Solutions for UAE Farms

In the UAE, where agriculture plays a significant role in sustaining the nation’s food security, high-quality agricultural oils and lubricants are essential for maintaining the efficiency and longevity of farming machinery. Agricultural engine oil is specifically designed to withstand the harsh conditions of farming operations, ensuring optimal performance for farm tractors, agriculture engines, and various farm equipment. Oil for farming helps in reducing engine wear and tear, minimizing downtime, and improving fuel efficiency, which is crucial for the success of UAE’s modernized farming practices. Reliable agriculture lubricants also play a key role in protecting engines from dirt, dust, and extreme temperatures, extending the life of agricultural machinery. Whether it’s farm tractor motor oil or specialized oils for farms, choosing the right products for agriculture engine oil maintenance ensures smoother operations and lower maintenance costs, allowing farmers to focus on productivity and sustainability. As the UAE continues to invest in agricultural innovation, the demand for high-performance agriculture oils remains strong, driving the need for quality and reliability in agricultural engine oils and lubricants.

Best Agricultural Engine Oils for Tractors and Farm Equipment

Choosing the right engine oil for tractors and oil for farms is essential for maintaining the efficiency and longevity of your machinery. Agricultural equipment works under tough conditions, making it crucial to use high-quality oils that provide superior protection, prevent wear, and ensure smooth operation. Oils like RUMANZA Trac-92 T agricultural lubricants are specifically designed for agricultural machinery, offering exceptional performance by reducing wear and preventing issues with the Power Take-Off (PTO) and these are ideal for heavy-duty diesel engines. Rumanza Tractor Universal Oil UTTO is also a reliable and cost-effective choice, offering great protection for diesel engines. Selecting the right engine oil tailored to the specific needs of your equipment will help reduce maintenance costs and ensure that your machinery continues to perform at its best oil engine for agriculture.

How to Get a Longer Working Life Out of Your Tractor

Extending the working life of your tractor involves regular maintenance and using high-quality lubricants. Start by adhering to a strict maintenance schedule, including timely oil changes, filter replacements, and checking fluid levels. Use the recommended agricultural engine oil to ensure optimal lubrication and protection. Regularly inspect and clean air filters to prevent engine strain. Keep the tractor clean to avoid dirt and debris buildup, which can cause wear and corrosion. Properly store the tractor when not in use, protecting it from harsh weather conditions. By following these practices, you can significantly extend the lifespan of your tractor and maintain its performance.

To get a longer working life out of your tractor, follow these tips:

- Regularly change the oil according to the manufacturer’s schedule

- Use the correct type and viscosity of oil for your tractor

- Clean and maintain the tractor regularly

- Monitor oil levels and top off as needed

- Avoid overloading or abusing the tractor

Which Parts of Tractor Need Lubricating?

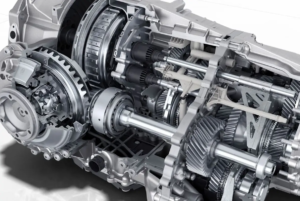

Several parts of a tractor require regular lubrication to ensure smooth operation and longevity. The engine is the primary component that needs consistent oil changes to maintain performance and prevent wear. The transmission and hydraulic systems also require specific oils to function correctly and prevent damage. Additionally, grease fittings on joints, bearings, and other moving parts need regular greasing to avoid friction and wear. The front axle and steering components should be lubricated to ensure proper handling and maneuverability. By regularly lubricating these parts, you can keep your tractor running efficiently and avoid costly repairs.

The following parts of a tractor require lubrication:

- Engine bearings and seals

- Gearbox and transmission components

- Axles and hubs

- hydraulic systems

Common Issues and Solutions

1. Overheating: Poor lubrication can cause excessive heat buildup. Solution: Use oil with the correct viscosity and thermal stability.

2. Sludge Formation: Dirt and contaminants can degrade oil quality. Solution: Regularly change oil and use high-quality filters.

3. Increased Fuel Consumption: Poor lubrication leads to higher fuel usage. Solution: Use synthetic oil for better efficiency.

How Does Oil Protect Tractor’s Engine?

Oil plays a crucial role in protecting a tractor’s engine and farming equipment oil by providing lubrication, cooling, and cleaning functions. It reduces friction between moving parts, preventing wear and overheating. The oil forms a protective film on engine components, reducing metal-to-metal contact and minimizing damage. It also helps dissipate heat generated by the engine, preventing thermal breakdown and maintaining optimal operating temperatures. Additionally, oil contains detergents and dispersants that keep the engine clean by preventing the formation of sludge and deposits. This ensures smooth engine performance and prolongs the lifespan of the tractor’s engine.

Oil protects a tractor’s engine by:

- Reducing friction and wear on moving parts

- Preventing corrosion and rust on metal components

- Cooling the engine by carrying heat away from hot spots

- Preventing leakage by sealing gaps between moving parts

What Factors Affect the oil used in agriculture?

Several factors can affect the performance and lifespan of agricultural engine oil. Temperature is a significant factor, as extreme heat can cause oil to break down, while cold temperatures can affect its viscosity. Contaminants such as dirt, water, and fuel can degrade oil quality, leading to reduced lubrication and potential engine damage. Operating conditions, including heavy loads and extended use, can increase oil degradation and the need for more frequent changes. Additionally, the type of oil and its agricultural lubricant additives can influence its stability and effectiveness. Regular monitoring and maintenance are essential to address these factors and ensure optimal oil performance.

Several factors can affect the performance of agricultural engine oil and agricultural machinery oil, including:

- Temperature: Extreme temperatures can affect viscosity and performance

- Contamination: Dirt, dust, and debris can compromise lubrication

- Load: Heavy loads can increase wear and tear on the oil

How to Know When Oil is Due for a Change?

Knowing when to change the oil in your agricultural equipment is crucial for maintaining its performance and longevity. Most manufacturers provide recommended oil change intervals in the equipment’s manual. Additionally, regularly check the oil level and quality using the dipstick. If the oil appears dark, dirty, or has a burnt smell, it’s time for a change. Modern equipment may also have oil life monitoring systems that alert you when an oil change is due. Consistently following these guidelines and conducting regular oil analysis can help you determine the optimal oil change intervals and keep your machinery running smoothly.

To know when oil is due for a change, check:

- The oil level regularly and top off as needed

- The color and consistency of the oil: dirty or cloudy oil may be due for change

- The oil’s viscosity: if it becomes too thick or thin, it may be due for change

- The manufacturer’s recommended maintenance schedule

FinalThoughts

Choosing the right agricultural engine oil and agricultural machine oil additives for maintaining a regular lubrication schedule are essential for ensuring the longevity and efficiency of farm machinery. By understanding the different types of oils, their properties, and how they protect and enhance engine performance, farmers can make informed decisions to keep their equipment in top condition. Regular maintenance practices, including timely oil changes and lubrication of critical components, play a significant role in extending the working life of tractors and other agricultural equipment or agriculture machinery lubricant. By prioritizing these aspects, farmers can achieve greater productivity, reduce downtime, and ultimately enhance the overall success of their farming operations.

FAQs

Regular oil changes are crucial for maintaining agricultural machinery. Follow these guidelines:

Manufacturer’s Recommendation – Check the manual for specific intervals (e.g., every 100-250 engine hours).

Oil Condition – Change if the oil appears dark, dirty, or has a burnt smell.

Usage Intensity – Heavy or dusty conditions may require more frequent changes.

Seasonal Changes – Switch oil viscosity when seasons change (e.g., winter/summer).

After Break-in Period – Replace oil after the initial break-in period for new machinery.

Regular oil changes ensure optimal performance, reduce wear, and extend equipment life.

Agricultural engine oil is specifically formulated to handle the unique demands of farm machinery, including heavy loads, prolonged use, and harsh environmental conditions. It contains additives that offer enhanced protection against wear, oxidation, and thermal breakdown, which are essential for maintaining the performance and longevity of agricultural equipment.

The frequency of oil changes depends on the manufacturer’s recommendations and the operating conditions of the tractor. Generally, oil changes are advised every 100-200 hours of operation. However, severe conditions such as dusty environments or heavy workloads may require more frequent changes.

Yes, synthetic oils can be used in farm equipment and often provide superior performance, especially in extreme temperatures and heavy-duty applications. Synthetic oils offer better viscosity stability, enhanced protection against wear, and longer oil change intervals compared to conventional oils.

Indicators that the engine oil needs changing include dark or dirty oil, a burnt smell, increased engine noise, and a noticeable decrease in engine performance. Checking the oil level and quality regularly using the dipstick can help identify when an oil change is due.

Key factors include the type of equipment, operating conditions, manufacturer’s recommendations, and oil viscosity grade. It’s also important to consider the oil’s additive package, which can impact performance and protection. Always choose oils that meet or exceed industry standards and certifications.

The best oil for agriculture depends on the type of machinery and application. Some commonly used oils include:

- Tractor Hydraulic Oil (THF or UTF): Used in tractors for hydraulic systems, transmissions, and wet brakes.

- 15W-40 Diesel Engine Oil: Ideal for agricultural equipment with diesel engines.

- Gear Oils (e.g., 80W-90, 85W-140): Used in transmissions and differentials of farm machinery.

- Hydraulic Fluids: Essential for hydraulic systems in harvesters, loaders, and sprayers.

15W-40 is a multi-grade engine oil primarily used in diesel engines found in:

- Agricultural tractors and machinery

- Heavy-duty trucks and construction equipment

- Generators and industrial engines

It provides good viscosity stability and protection in both cold and hot conditions.

Farmers typically use a variety of oils depending on their machinery:

- Engine Oils: 15W-40 or 10W-30 for diesel and gasoline engines.

- Hydraulic Oils: AW-32, AW-46, or AW-68 for hydraulic systems.

- Gear Oils: 80W-90 or 85W-140 for transmissions and differentials.

- Grease: Lithium or calcium-based grease for lubrication of joints and bearings.

- Conventional Oil: Basic mineral oil for older engines.

- Synthetic Oil: High-performance oil with better protection and longevity.

- Synthetic Blend Oil: A mix of synthetic and conventional oil for better performance at a lower cost.

- High-Mileage Oil: Designed for vehicles with over 75,000 miles to reduce wear and leaks.

Role of Rumanza Anti-Wear Additives For Engine & Machinery

Role of Rumanza Anti-Wear Additives For Engine and Machinery Longevity Discover More The operational lifespan of engines and industrial machinery is heavily influenced by friction, thermal stress, and mechanical wear. Over time, these factors lead to component degradation, reduced efficiency, and increased maintenance costs. To combat these challenges, Rumanza anti-wear (AW) additives have emerged as a critical solution in lubrication technology. This in-depth analysis explores: The chemical composition and working mechanism of Rumanza AW additives. Their impact on engine and

When Should You Use RUMANZA Speed-GT Ultra Motor Oil? A Complete Guide

When Should You Use RUMANZA Speed-GT Ultra Motor Oil? A Complete Guide Discover More Introduction Rumanza Speed-GT Ultra is a high-tech, low-friction engine oil specifically designed for RENAULT vehicles (Renault, Dacia, Samsung) fitted with gasoline and diesel engines requiring a Renault RN17 FE specification lubricant. The Mid-SAPS technology, in combination with unique low-friction properties, reduces fuel consumption and, thus minimizes pollutant emissions. The reduced levels of Sulfated Ash, Phosphorous and Sulphur of Speed-GT4 protects and extends lifetime of modern after-treatment

RUMANZA ATF-XD-II Full Synthetic ATF – Premium Transmission Fluid

RUMANZA ATF-XD-II Full Synthetic ATF – Premium Transmission Fluid Discover More Introduction to Transmission Fluids and Their Critical Role in Vehicle Performance Transmission fluid is the lifeblood of any vehicle’s transmission system, playing a crucial role in lubrication, cooling, and hydraulic function. Unlike engine oil, which primarily lubricates moving parts, automatic transmission fluid (ATF) must also facilitate smooth gear shifts, prevent wear, and maintain optimal pressure in complex transmission systems. With advancements in automotive engineering, transmissions have become more sophisticated, requiring high-performance ATF formulations that

Boost Engine Life Instantly with Rumanza TBN Booster Additive!

Boost Engine Life Instantly with Rumanza TBN Booster Additive! Discover More In the world of automotive maintenance, engine longevity is a top priority for vehicle owners, fleet managers, and mechanics alike. Over time, engines suffer from wear and tear, sludge buildup, acid corrosion, and oil degradation, all of which contribute to reduced performance and costly repairs. Fortunately, Rumanza TBN Booster Additive provides an instant solution to these problems by enhancing the Total Base Number (TBN) of engine oil, ensuring superior protection and extended engine life. This in-depth

Extend Your Tractor’s Lifespan with Rumanza UTTO Oil – A Comprehensive Guide

Extend Your Tractor’s Lifespan with Rumanza UTTO Oil – A Comprehensive Guide Discover More Tractors are the backbone of modern agriculture, performing demanding tasks such as plowing, tilling, hauling, and powering attachments. Given their heavy workload, ensuring optimal performance and longevity is crucial. One of the most effective ways to protect your tractor’s critical systems is by using Rumanza UTTO (Universal Tractor Transmission Oil), a high-performance lubricant engineered to enhance durability, efficiency, and reliability. The Science Behind UTTO Oil: Why It

Best Agriculture Tractor Oil: RUMANZA Trac-92 T Explained in Depth

Best Agriculture Tractor Oil: RUMANZA Trac-92 T Explained in Depth Discover More Agriculture tractors are indispensable in modern farming, serving as the primary workhorses for plowing, tilling, planting, and harvesting. However, the efficiency, durability, and overall performance of these machines depend significantly on the quality of the tractor engine oil used. Selecting the right agriculture tractor oil is not just about lubrication; it directly impacts fuel efficiency, engine longevity, and operational costs. Among the various options available, RUMANZA Trac-92 T has emerged as a leading high-performance tractor

Upgrade Your Drive with Rumanza CVT NSIII – Benefits & Features

Upgrade Your Drive with Rumanza CVT NSIII Benefits & Features Discover More The automotive industry is undergoing rapid advancements, with manufacturers continuously innovating to improve fuel efficiency, driving comfort, and engine performance. One of the most critical yet often overlooked components in modern vehicles is the transmission system, specifically the Continuously Variable Transmission (CVT). Unlike traditional automatic transmissions, CVTs provide seamless gear transitions, leading to smoother acceleration, better fuel economy, and reduced engine strain. Understanding CVT Technology and the Need

Rumanza Dual Clutch Transmission: Analysis of Advantages, Limitations, and Industry Impact

Rumanza Dual Clutch Transmission: Analysis of Its Advantages, Limitations, and Industry Impact Discover More The automotive industry is undergoing a transformative phase, with manufacturers relentlessly pushing the boundaries of performance, efficiency, and driving engagement. Among the most groundbreaking innovations in recent years is the Dual Clutch Transmission (DCT), a sophisticated gearbox technology that bridges the gap between manual and automatic transmissions. Rumanza, a pioneering name in transmission systems, has introduced an advanced DCT that is redefining expectations in terms of

Rumanza Gasoline Petrochemicals: A Strategic Force in the Global Energy Sector

Rumanza Gasoline Petrochemicals: A Strategic Force in the Global Energy Sector Discover More Rumanza Gasoline Petrochemicals: Corporate Overview & Market Dominance 1.1 Historical Evolution & Industry Positioning Founded in the late 20th century, Rumanza Gasoline Petrochemicals began as a regional fuel supplier before rapidly expanding into a vertically integrated energy conglomerate. Today, it operates: 12+ high-capacity refineries (crude processing capacity: 2.5 million barrels per day) 40+ petrochemical plants producing ethylene, propylene, benzene, and specialty chemicals Global supply chain networks across Asia, Africa, Europe, and the Americas Market Share & Financial

What Is Diesel Fuel Oil: Benefits & Types of Diesel Fuel

What Is Diesel Fuel Oil: Benefits & Types of Diesel Fuel Discover More Diesel fuel oil is one of the most crucial energy sources powering global industries, from transportation and agriculture to construction, power generation, and shipping. Its efficiency, reliability, and ability to produce high torque and power make it the preferred fuel for heavy-duty machinery, trucks, buses, and generators. But what exactly is diesel fuel oil? What are its benefits, types, and environmental impact? And how is the diesel