Head Office

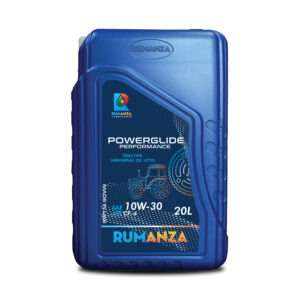

Rumanza group of companies is a leading producer and manufacturer of Premium Quality lubrication, Base oil & Oil Derivatives in UAE. The company is based in Dubai, having various businesses including Import/ Export, Whole sale & manufacturing of industrial lubricants and Engine greases.

Copyright 2024 © Rumanza Group Of Companies. All Rights Reserved.